Textile architecture by MDT-tex

Our versatile possibilities in textile architecture

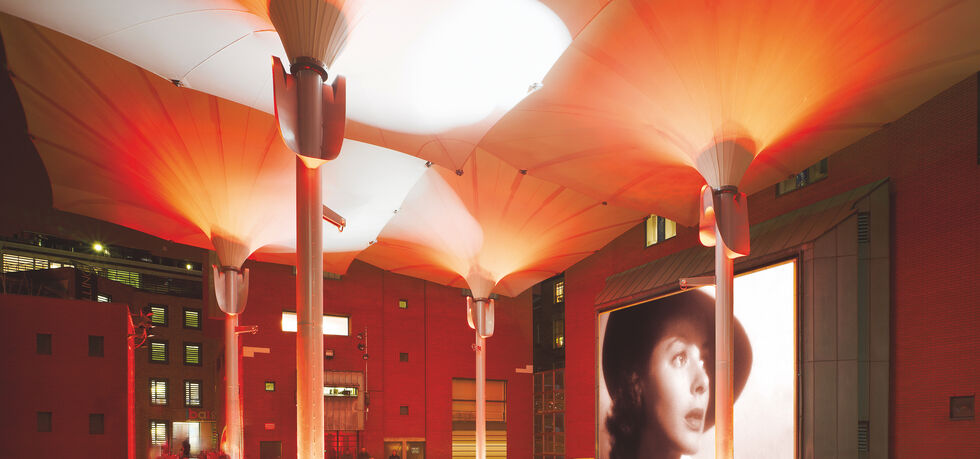

Our services go far beyond the production of classic sunshades and shading solutions. At our production sites, we work closely with designers, architects and structural engineers to implement large-scale textile architecture. Convertible sunshades are just as much a part of our product range as textile facades, lightweight architecture and other products.

Thus, since our foundation in 1990, we have continuously expanded our high-quality product range and have meanwhile made ourselves a professional supplier for individual shading concepts, weather protection solutions and textile architecture with our worldwide projects and international locations.

At MDT-tex, we manufacture convertible sunshades and various other forms of textile architecture. Our shading and weather protection solutions are used for catering and hotel business, for municipal facilities and public places, for events and exhibitions or for high-quality equipment for company buildings. Our range of products includes, for example, the following textile architectures:

- convertible canopies and solar carports

- Foldable PTFE sunshades and membrane construction

- Textile facades and roofs

- Fixed free-form textile structures

Depending on the model, special functional features such as water drainage, water storage, solar panels, lighting and heating elements can be incorporated to add value to shading concepts.

In addition to our many years of experience and expertise, our in-house production is a major advantage. Here, we can continuously monitor the high quality requirements of our products, react promptly to changes, and work with you to develop customized solutions from a single source, from design to final implementation.

Our production site in Hardheim, Baden-Wuerttemberg

We are particularly proud of our production site in Hardheim, where more than 100 employees work on the individual implementation of your textile architecture. We use only the highest quality "state of the art" manufacturing methods and thus achieve a particularly high level of safety, durability and processing quality.

In Hardheim, we are constantly creating a wide variety of projects, such as free-form sculptures made of steel, aluminum and wood, each using practical lightweight construction methods. For our high safety standards, we have our own test site for the construction where the mechanical testing also takes place.

However, to ensure that statics and design, function and form, safety and beauty are implemented with equal care right from the start, our design and engineering team comes into play.

From design to construction: engineering and design from a single source

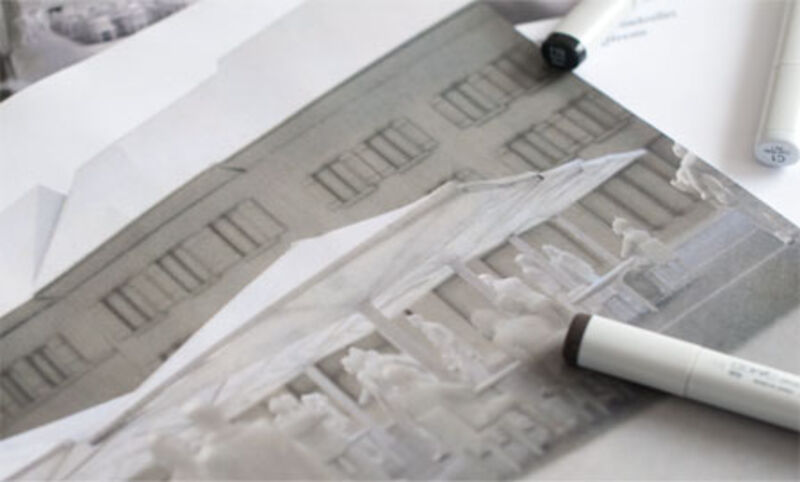

Lightweight architecture and membrane construction should ultimately appear weightless and blend in harmoniously without compromising on safety. To achieve this, our engineering team brings together structural engineers, mechanical engineers, technical draftsmen and application experts who guarantee structural safety and also ensure that raw materials are used as efficiently as possible.

In addition, there is a team of designers and membrane designers to also perfect the visual design of the textile architecture. In this way, the convertible sunshades remain under one roof from the concept phase to the execution drawing to the final realization, which at the same time ensures quality and a smooth process and also shortens the processing time enormously, as long waiting times for external service providers are eliminated.

A small insight into our production method

For our international projects we offer local contact persons at our production and warehouse locations in the USA, Latvia, Croatia, Australia and Switzerland. As the heart of MDT-tex, we are particularly proud of our location in Hardheim in Baden-Württemberg.

At this production site, we can implement architectural concepts up to 30 meters in length and other large-scale projects in our spacious facilities, for example. Here, we have more than 10,500 m² of production and storage space and automated processing centers for steel and aluminum at our disposal, where even the most visionary, bold projects can be realized.

The MDT-tex production hall in Hardheim offers a height of 30 meters and is equipped with two 25 t cranes. And we also rely on large-scale solutions for the development and processing of our coverings.

For the production and cutting of our own MDT-tex membranes, we have our own Sailing Loft with over 1000 m² of space. This allows us to offer literally tailor-made solutions for a wide range of requirements, in terms of shape, size, handling and choice of materials.

Conclusion textile architecture

Even though lightweight architecture, foldable PTFE sunshades and textile architecture with its organic shapes and appealing design seems almost weightless, there is an extremely sophisticated know-how in terms of engineering, safety and statics behind it.

Together with a shapely design, textile facades and roofing concepts are thus created for public or commercially used spaces, offering visitors protection from the weather and at the same time creating inviting spaces.

Finally, the selection of suitable materials also plays a role in developing durable, weatherproof and permanently protective projects. Our individual additional features such as heating, lighting, rainwater management or solar surfaces create practical and inviting added value for you and your visitors.

Expertise and advice since 1990

And last but not least, we offer all these services and our decades of expertise in our in-house production with personal consultation, so that you are always informed about the state of affairs, the high quality is maintained and even short-term changes can be implemented promptly.

Finally, you can see for yourself in our numerous international references which unique and visionary projects we have already successfully implemented in a wide variety of countries and which also serve as walk-in business cards for us.