FROM ARCHITECTURE TO SATISFACTION

OUR PRODUCTION RUN

- Scoping

The basis for every project is set-up in cooperation with our customers. Beforehand the entire surrounding and basis is carefully evaluated to set specifications together jointly with the customer. A detailed understanding of the whole order is needed for a precise project estimation and controlling. A major parameters is the ratio between functionality and aesthetic design.

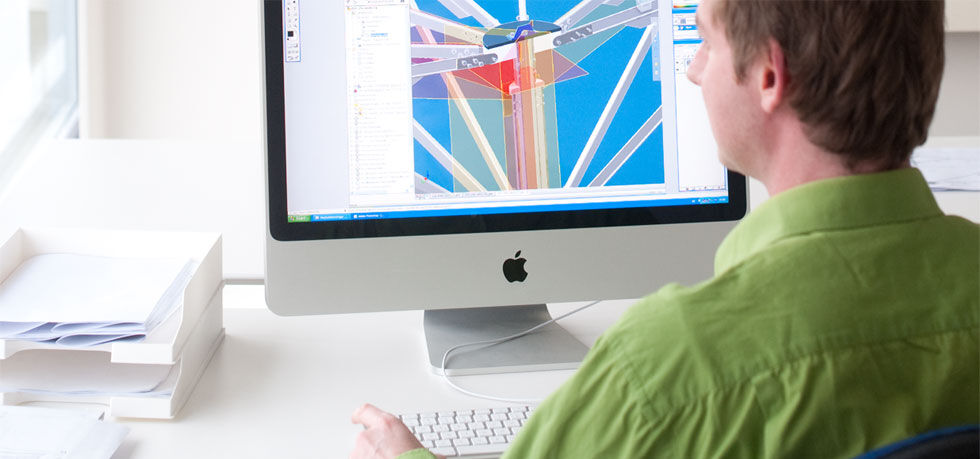

- Design Process

The most challenging part is the design process, where MDT’s creativity and know- how melts together. We aim to meet maximum standards with regard to technical and aesthetic aspects , regardless how challenging obstacles might be. This to be ensured by high ranking architects and engineers led by our creative director Enlai Hooi.

- Engineering

By steadily developing new technical textiles, coatings, processes and high-tech materials, there are always new opportunities to use for our engineers. CAD visualizations are being created while 3 D formfinding programmes, which are responsible for the perfect textile cut, provide " guaranteed to fit " membranes. For single umbrellas as well as for complex sun- and rain-protection systems.

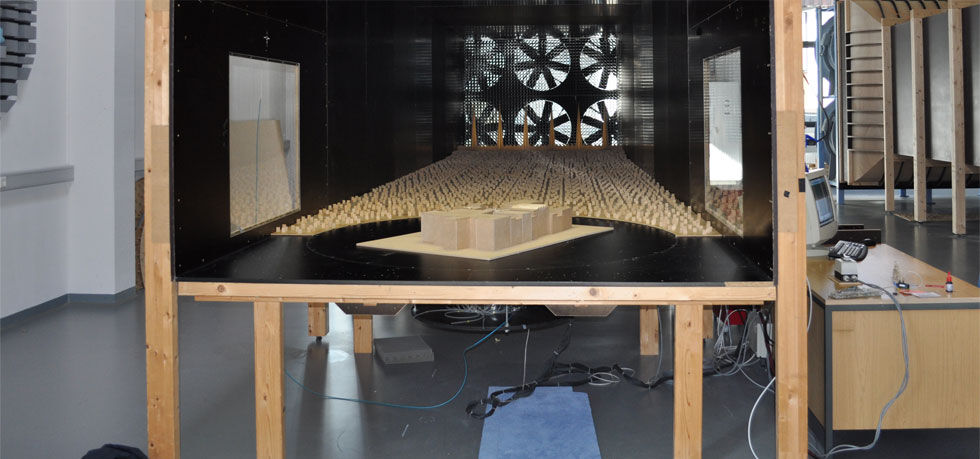

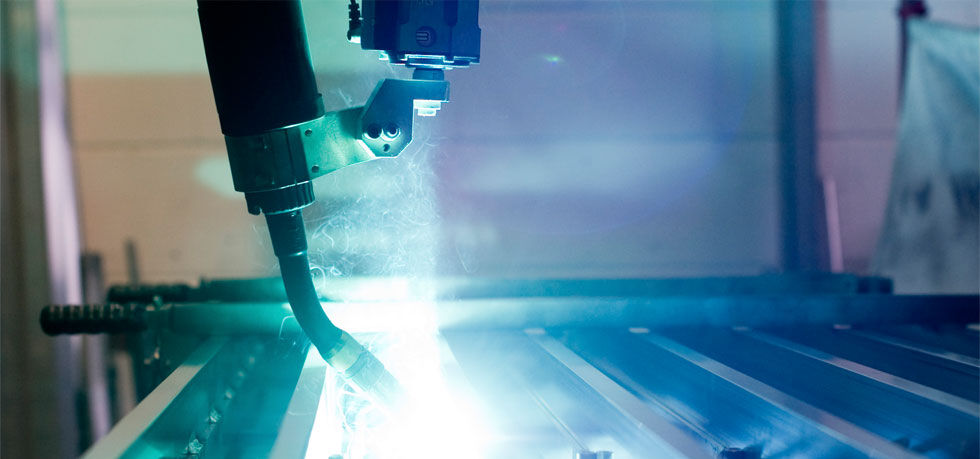

- Testing

The toughest stage remains the testing phase. Many years of experience enable us to realize prototypes rapidly in-house. Before first prototypes are build, we test them in virtual reality. The combination of specialized software programs simulates opening and closing procedures of complex rods and textiles. Test-parts may be produced with an in-house 3-D printer and CNC-router. We leave nothing to chance - except the weather.

- Manufacturing

Manufacturing and assembling in work shops with 12m ceiling heights allow a fully controlled "in house" finishing of giant umbrellas , as several up to 25 ton cranes are ready to move and transport .This is the only way to meet highest demands.

- Service

Our service competences are affected by the same preciseness than the production. Experienced employees control the installation and carry out regular maintenance work for installations – which we recommend for larger projects. MDT is capable to take care of our customers being satisfied with our products for a long time!